POWDER INJECTION MOLDING TECHNOLOGY FOR

LARGE METAL & CERAMIC COMPONENTS & SYSTEMS

SME

TECHNICAL PAPER (note: figures removed)

Society of Manufacturing Engineers

One SME Drive, Dearborn, MI 48121

313-271-1500

www.sme.org

Boney A. Mathew

Mathson Materials Technology, Inc.

1845 Thunderbird Street

Troy, MI 48084, USA

ABSTRACT

Traditional applications for metal injection molding or

ceramic injection molding have been small net shaped

parts exhibiting design and economic benefit over

wrought or cast components. A new water based agar

binder system for metal and ceramic injection molding

has been developed that offers the ability to produce

large thick parts in range of 1 to 2 kg which are

competitive with those produced by investment casting.

Other significant advantages of this system are a clean

and rapid debind, and the ability to mold into soft

tooling. As a result, savings are achieved not only by

eliminating machining and other processing steps but

also by reduced development and inventory costs. This

technology is applied to a variety of automotive

applications such as, EGR System, Exhaust System, Oxygen

Sensors, Electrical Components, Engine Components, etc.

Many of these applications require demanding mechanical

properties. For an example, the average tensile

properties of the 17-4PH stainless steel alloy is

compared against wrought and cast properties, tensile

properties were essentially equivalent to wrought and

exceed typical cast properties. Due to the relative low

molding pressure and temperature required for water

based agar binder, soft tooling may be employed in place

of hardened tools for production runs less than 10,000

parts. Primary materials using water-based agar binding

systems are Stainless Steel, Alumina, Zirconia, Steatite

and other metal alloys. This injection molding process

allows economical competition with large net shaped

process techniques such as Investment Casting.

The importance of this paper is that it allows designers

and engineers to utilize Ceramics and Metal Alloys

Injection Molding Technology to combine several machined

or cast components into one large cost effective system

eliminating several manufacturing steps.

INTRODUCTION

The injection molding for metal and ceramic powders are

production technologies that are experiencing rapid

growth worldwide. This growth is mainly in the USA,

Europe and Asia. Ceramic Injection Molding (CIM) and

Metal Injection Molding (MIM) is a manufacturing

technique for making complex and precision components.

Ceramic and Metal Injection molded components compete in

the market place against parts made using various

processes. Investment Casting, Slip Casting, Machining

and Powder Forging are examples of the competitive

processes. An important part of CIM and MIM is the

binder in the feedstock technology and removal of binder

from the part after injection molding. One binder

technology currently established is the polyacetal-based

binder. The polyacetal based binder systems uses a

catalytic debinding utilizing Nitric Acid as

depolymerization Catalyst.1. New development in binder

technology such as aqueous based agar binder systems for

metal and ceramic offers the ability to produce large

thick parts in the range of 1 to 2 kg which are

competitive with those produced by Investment Casting.

THE AGAR BASED AQUEOUS BINDER SYSTEM

This binder is based on agar, a polysaccharide derived

from seaweed, which is water-soluble. Metal or ceramic

powder is mixed with the water, agar and a gel

strength-enhancing agent having the form of a borate

compound such as calcium borate, zinc borate, etc. to

form feedstock pellets that can be injection molded into

components2.

The use of such gel forming materials in combination

with a gel strength-enhancing additive substantially

reduces the amount of binder (typically 2-3 wt %) needed

to form a self-supporting article. Thus complex

components produced from agar with gel strength

enhancing borate compounds imparts high strength and

deformation resistance. It is critical to have adequate

part green strength in order to handle components

without damage after Injection Molding Process.

Typically, 55% by volume (18-wt. %) water is added to

the mixture, which performs the dual function of being a

solvent and a carrier for agar containing mixtures 3.

The mixture may also contain a variety of additives,

which can serve any number of useful purposes. For

example, dispersants may be employed to ensure a more

homogeneous mixture. Biocides may be used to inhibit

bacterial growth in the molding compositions, in

particular if they are to be stored for a long period of

time4.

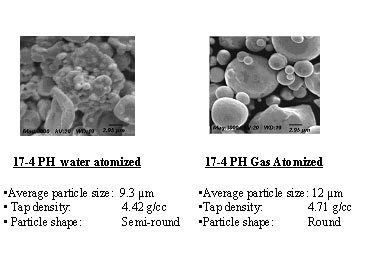

The metal powder used is typically under 20 micrometers

and is made by gas or water atomization is shown in

Figure 1. The feedstock with a uniform composition of

high solid loading is desirable in the production of

Injection Molded parts. The higher solids loading

feedstock imparts lower shrinkage when the molded parts

are dried and fired, facilitating dimensional control

and reducing tendency for cracks during sintering

process, in turn higher yields of acceptable product

with lower scrap rates.

Figure 1. Water and Gas Atomized 17-4 PH Stainless Steel

Powders

The solid loading of the feedstock is near 92-wt % (61

vol. %), the balance consisting of water. The feedstock

is produced by passing mixture composition directly

through a twin screw extruder and cutting the extrudate

into pellets as it exits the die. Alternate method of

feedstock production is by mixing the mixture

composition in a sigma blender and then shredding the

blended mixture into pellets.

The feedstock is injection molded to the desired shape,

typically around 85o C melt temperature with a molding

pressure in the range of 150 psi to about 800 psi. At

injection molding temperature of 85o C the feedstock is

relatively fluid and is easily injection molded into a

net shape part. Compared to plastic injection molding,

water based agar system is molded at lower melt

temperature and injection pressure.

Once the feedstock temperature is cooled in the mold to

near room temperature, the green part can be ejected

from the mold. Typically injection molding cycle time is

in the order of 30 seconds depending on the part size.

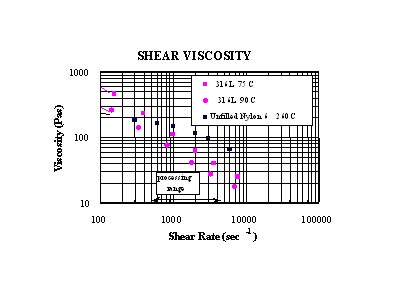

The viscosity of the feedstock is similar to that of

unfilled Nylon 6 during injection molding process, as

shown in Figure 2. Due to the relative low molding

pressure and temperature required for water based agar

binder, soft tooling may be employed in place of

hardened tools for production runs less than 10,000

parts. 3D systems have developed SLA rapid tooling

fabricated directly from electronic files of a part. A

polymeric tool can be grown in a matter of hours at a

relatively low cost. Using water-based agar feedstock

prototype parts can be molded in a SLA tool.

Figure 2. Aqueous Based Agar Binder 316L Stainless Steel

Viscosity Comparison with Unfilled Nylon 6 Polymer

The green part is left open in the ambient air for

approximately 1 hour for drying. No separate debind step

is required, as is necessary for traditional MIM

feedstock’s. For water based feedstock debind step is

incorporated into first one (1) hour cycle of the

sintering process. During the sintering process, the

binder pyrolizes in the sintering furnace and carbon is

removed during the sintering cycle. The sintering is

typically performed in Hydrogen medium for metal alloys

for carbon control, and air is typically used as a

medium for ceramics sintering. Sintering temperatures in

the range of 1300o – 1400o C are typically employed for

stainless steel alloys, and sintering temperatures in

the range of 1600o – 1700o C are typically employed for

Ceramic material such as Alumina. Batch or continuous

sintering furnaces can be employed for debinding/sintering

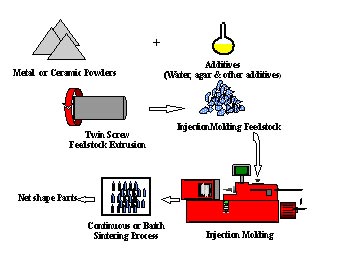

based on production volume requirements. The schematic

of ceramic and metal injection molding process using the

water based agar binder system is shown in Figure 3.

Figure 3. Schematics of Ceramic and Metal Injection

Molding Process using Water Based Agar Binder System

MICROSTRUCTURAL AND MECHANICAL PROPERTIES

The mechanical properties in 17-4PH Stainless Steel is

defined by uniform formation of martensite, which

requires control of carbon during sintering process. Due

to the low level of binder in water based agar

feedstock, as well as its relative ease in removal

during sintering process, carbon can be tightly

controlled. The typical specification of 17-4PH

stainless steel is below 0.07 wt % carbon. Carbon

Analysis in sintered components with a cross sectional

thickness of 19 millimeters manufactured from water

based agar system; carbon level is measured at .01% wt

%. The core and near surface of the component show a

uniform formation of martensite, demonstrating the tight

control of carbon achieved through the use of water

based agar feedstock system (5).

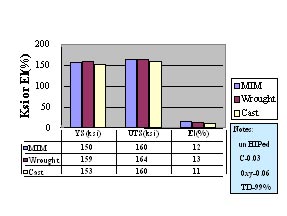

Many of the automotive applications require demanding

mechanical properties. Figure 4 lists the average

tensile properties of the 17-4PH stainless steel alloy6.

The samples consisted of two batches, UnHIPed and HIPed,

which were heat-treated to the H1025 condition. The 9.52

millimeter thick tensile bars employed in the study had

an average sintered density of 98.5 + 0.5%. The tensile

properties of water based agar system 17-4PH stainless

steel were equivalent to wrought and exceeded typical

cast properties. It was found that HIPed samples had

improved tensile properties due to 1-2% reduced porosity

compared to UnHIPed material (7).

Figure 4. Average 17-4PH H1025 Stainless Steel Tensile

Data

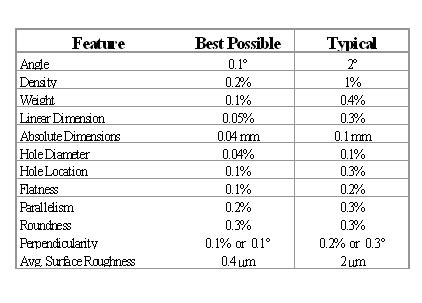

DIMENSIONAL

CONTROL

Parts molded from water based agar system; there is an

approximate 2% shrinkage during drying and 17% shrinkage

during sintering process. This shrinkage is repeatable

resulting in control in dimensional tolerances to about

0.5% to a 3-sigma production yield. Tighter tolerances

can be obtained for critical dimensions through the use

of setters during the sintering process. Figure 5 shows

the current dimensional tolerance limits of Ceramic and

Metal Injection Molded Components (8).

Figure 5. Current Dimensional Tolerance Limits for

Ceramics and Metal Injection Molded Components

AUTOMOTIVE APPLICATIONS

The water based agar binder system is available in a

variety of stainless steel alloys such as 17-4PH, 316L,

410 etc. as well as tungsten and nickel based super

alloys such as GMR 235, Hastelloy X etc. Additionally,

ceramics such as Alumina, Zirconia and Steatite can be

manufactured using water based Agar binder system.

Figure 6 shows a sintered automotive turbo charger wheel

made of the nickel alloy GMR2359. Figure 7 shows

balanced valve shaft for EGR system using 316L stainless

steel. Figure 8 shows automotive exhaust and electrical

components manufactured from Alumina and Steatite

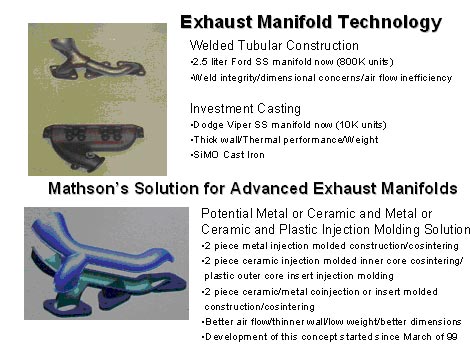

Ceramics. Figure 9 shows advanced research concepts by

Mathson Industries on Exhaust Manifold technology using

metal, ceramic and metal or ceramic and plastic

Injection Molding solution.

Figure 6. Sintered Automotive Turbocharger Wheels made

of the GMR235 Nickel Alloy

Figure 7. Balanced Valve Shaft for EGR System using 316L

Stainless Steel

Figure 8. Automotive Exhaust and Electrical Components

Manufactured from Alumina and Steatite Ceramics

Figure 9. Advanced Exhaust Manifold Technology using

Metal or Ceramic and Metal or Ceramic and Plastic

Injection Molding Solution

CONCLUSION

Ceramic and Metal Injection Molding offers the ability

to produce large thick parts which are competitive with

those produced by Investment Casting. The mechanical

property of Injection Molded stainless steel alloy is

equivalent to wrought and exceeds typical cast

properties. Due to low molding pressure and temperature

required for Injection Molding, soft tooling could be

used for low production runs. Ceramics and metal alloys

Injection Molding can combine several machined or cast

components into one cost-effective product eliminating

several manufacturing steps.

Producing large parts such as exhaust manifolds in high

volumes can create a chain effect. For example the

automotive exhaust manifold annual usage in North

America exceeds more than 17 million units and each

manifold weighs several pounds, the total annual usage

of the material will be several million pounds. This

will allow raw material suppliers to produce powders at

a reasonable cost. The feedstock price will decrease, as

the powder price is the largest cost component of the

feedstock. This will then increase the potential for

part suppliers to produce parts at a competitive price.

This will enable PIM technology to produce other

applications, which currently cannot be produced due to

prohibitive feedstock cost.

ACKNOWLEDGEMENTS

The author would like to thank Cathy Mathew and Jane

Salvati of Mathson Industries, Inc. for their valuable

suggestions and assistance with this project.

AUTHOR’S BIOGRAPHY

Boney A. Mathew is President & CEO of Mathson

Industries, Inc., Mathson Materials Technology, Inc. and

Mathson Intellectual Technology, Inc., Troy, Michigan,

USA. Mathson Industries is a leading supplier of

Ceramics, Metal Alloys, Elastomers, and Plastics

Injection Molded Systems and Assemblies, globally.

Mathson Materials Technology is a leading materials

supplier of Ceramics and Metal Alloys for the Powder

Injection Molding Industry. Mathson Intellectual

Technology provides Patented New Products and

Technology, globally.

Mr. Mathew’s background includes eighteen years in the

automotive and plastics industry.

Prior to starting Mathson Industries, Inc., he was a

Marketing and Technical Executive for Nyltech North

America - Joint Venture of Rhone-Poulenc - France and

Fiat - Italy.

He also served as Plastics Manager for Teleflex, Inc.’s

Automotive, Aerospace and Medical Company. Mr. Mathew is

the inventor and co-inventor of several patents,

including “Method of Making Fluorocarbon Coated

Composite Braided Hose Assemblies”, “Hose End Fitting

Assembly” and “Expanded Fluoropolymer Tubular Structure,

Hose Assembly and Method for Making Same”.

He is a member of the Society of Plastics Engineers,

Society of Automotive Engineers, APMI and ASEI. He has

published and presented twelve technical publications on

various plastics, ceramics, metals and composites at

various international technical conferences and is the

co-author of “Passage to India, A Comprehensive Study on

the Indian Automotive Industry”.

Mr. Mathew earned Bachelor of Science and Master of

Science degrees in Plastics Engineering from the

University of Massachusetts, Lowell, Massachusetts USA.

REFERENCES

1. German, R., & Bose, A., “Injection Molding of Metals

& Ceramics”, Metal Powder Industries Federation, 1997,

pp. 209-210.

2. Fenelli et al., “Gel Strength enhancing additives for

agaroid-based Injection Molding Compositions”, United

States Patent Number 5,746,957, May 5, 1998, p.4.

3. ibid., p. 6

4. ibid., p. 6

5. Lasalle, J., “Net Shape Processing of Metals Using

and Aqueous – Based Injection Molding Binder”.

6. ibid., p. 3

7. ibid., p. 4

8. German, R., opcit. p. 288.

9. Lasalle, J., opcit., p. 5.

|