Automotive Air Intake Manifold Application using Nylon

6,6 Composite Material

SAE

TECHNICAL PAPER SERIES 1999-01-3011 E

Boney A. Mathew

Mathson Industries, Inc.

Dr.

Helio Wiebeck

Engenharia Quimica

University of Sao Paulo

Copyright © 1999 Society of Automotive Engineers, Inc.

ABSTRACT

There are many

advantages to air intake manifolds molded from Nylon 6.6

Glass reinforced composite material versus a

pressure-cast aluminum manifold. Weight is significantly

lowered and production costs generally are reduced.

Performance improves with the precise control of the

interior surface finish and reduced air induction

temperatures. The Nylon 6,6 Glass reinforced composite

material can be molded into intricate shapes by

injection molding or lost-core process with reduced

machining operations as well as Nylon 6,6 material is

easily recycled. Production costs will continue to

decrease as optimization of material, process and part

integration increases.

This study

evaluates Nylon 6,6 Glass reinforced composite material

in terms of the intake manifolds material key

requirements such as thermal, heat aging, fatigue,

impact, creep, stress and chemical resistance including

multi fuels. This study would assist engineers in

designing intake manifolds using Nylon 6,6 Glass

reinforced composite material.

INTRODUCTION

For over 25

years Nylon 6,6 Glass reinforced composite material has

been used in under the hood applications. Some of the

under the hood applications using Glass reinforced Nylon

6,6 are brake and power steering fluid reservoirs,

radiator end tanks, fuel injectors, etc. In recent years

Glass reinforced Nylon 6,6 composite has been used for

injection molded and loss core molded air intake

manifold.

The Nylon 6,6

composite offers several economic benefits. An air

intake manifold made from Nylon 6,6 composite can be

molded with snap-on or clip-on features due to the

strength and flexibility of the material. This

significantly reduces assembly costs as much as 15 –

20%. The Nylon 6,6 composite manifold requires no paint,

is non-corrosive and non-porous, unlike cast aluminum

which requires costly finishing steps.

The improved

volumetric efficiency of an intake manifold made from

Nylon 6,6 composite is due to its inherent insulating

properties. The Nylon 6,6 composite can be designed and

molded with greater flexibility than cast aluminum. The

manifold can be produced with a smoother, streamlined

interior, resulting in increased airflow to the engine,

which is a key factor in increasing horsepower of the

engine.

An air intake

manifold molded from Nylon 6,6 composite is an important

factor when faced with the proposed stricter corporate

average fuel economy (CAFÉ) regulations.

In short, Nylon

6,6 Glass reinforced composite offers several

advantages. It saves money, reduces weight, ease of

assembly, better insulation, improved airflow, excellent

strength to weight ratio and is recyclable.

EXPERIMENTAL

In order to

study the effect the automotive environment has on the

long term mechanical durability of Nylon 6,6 Glass

reinforced composite for air intake manifolds, the

following methodology was established:

-

Characterize the material by performing physical

properties tests.

- Expose the

material to various temperatures to evaluate thermal

resistance of the material in order to simulate

conditions under the hood.

- Expose the

material to fuels to evaluate chemical resistance of

the material.

MATERIAL

SSD 330 KNF, 33%

Glass reinforced polyamide 6,6 provided by Nyltech North

America.

EQUIPMENT

A 70mm ZSK 70

Werner and Pfleiderer twin screw extruder was employed

for compounding the material.

PHYSICAL

PROPERTIES TEST

Test specimens

were molded and tested using SSD 330 KNF material to

obtain physical properties of the material. The test

specimens were exposed to various temperatures and fuels

to understand the long term properties which would

assist in qualifying this material for intake manifold

applications.

RESULTS AND

DISCUSSION

This study was

conducted to characterize and to qualify Nylon 6,6 Glass

reinforced composite for intake manifold applications.

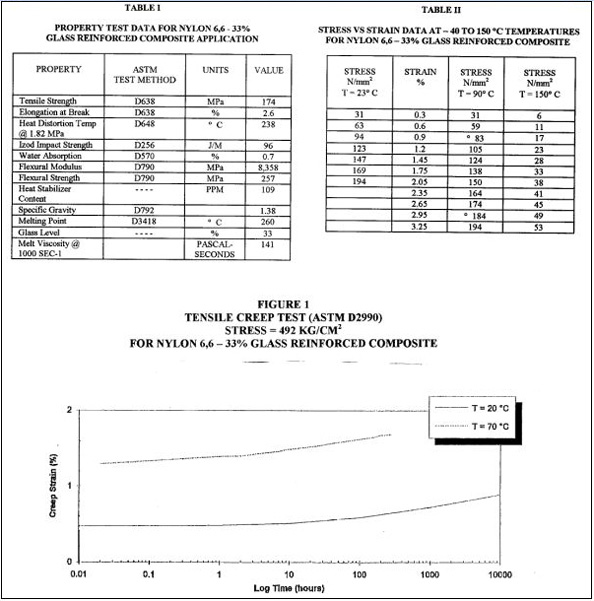

Table I shows

the physical properties data for Nylon 6,6 – 33% Glass

reinforced composite material. Table II shows stress

versus strain data at –40º to 150ºC for Nylon 6,6 – 33%

Glass reinforced composite. As expected at -40ºC at

given strain stress is maximum and at 150ºC stress is

minimum. This is due to viscoelastic relaxation's

corresponding to the onset of various types of internal

motion with increasing temperature (1).

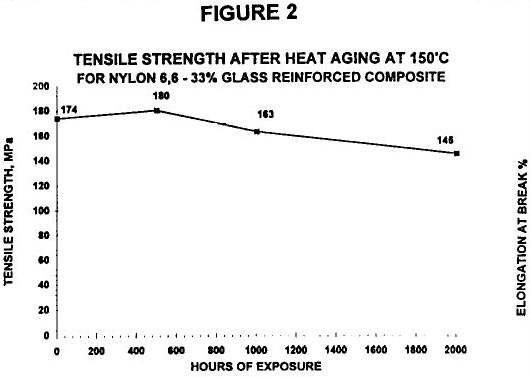

Figure 1

graphically shows tensile creep of the Nylon 6,6 – 33%

Glass reinforced composite. A percentage creep at 70ºC

is higher than at 20ºC. At higher temperatures, the

atoms and groups in the polymer molecules acquire an

increasing amount of thermal energy, causing them to

vibrate and move about. The higher the temperature, the

greater the thermal motion. The larger the sequences of

atoms in the polymer chain which become mobile, and in

turn increase creep at higher temperature (2).

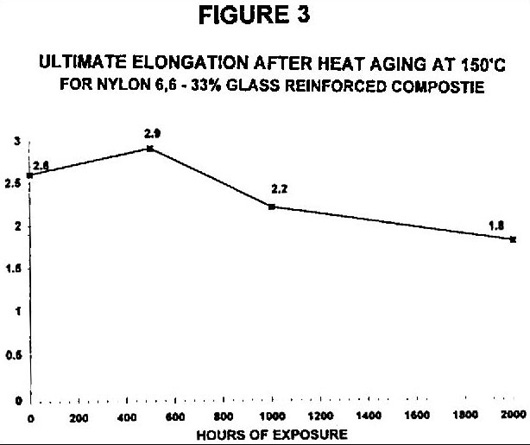

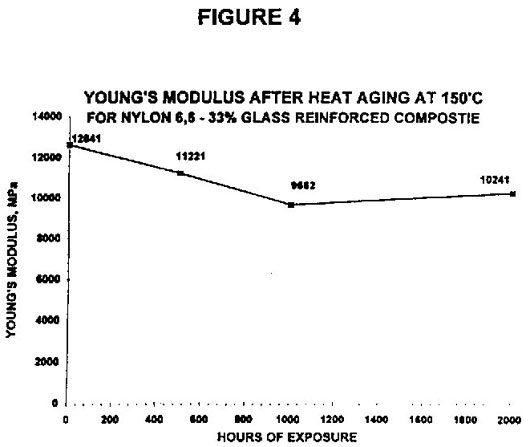

Figure 2, 3 and

4 shows the effects of heat aging at 150ºC on tensile

strength, ultimate elongation, and Young's modulus for

Nylon 6,6 – 33% Glass reinforced composite. After 2000

hours at 150ºC Nylon 6,6 – 33% Glass reinforced

composite showed good thermal durability based on

retention of the properties. The properties after 500 to

1000 hours remained fairly constant or increased

slightly. This indicated that while chain scission is

occurring on the surface due to oxidation, chain linking

(solid-state polymerization) occurs internally,

resulting in a constant or higher stiffness.

Additionally, it is attributed to stress relieving and

further crystallization at 150ºC.

The reduction in

properties at 2000 hours at 150ºC is primarily caused by

free radical chain scission and cross-linking of the

polymer molecules close to the surface. Three primary

mechanisms that change the mechanical properties of a

polymer exposed to higher temperatures are chain

scission, cross-linking and oxidation. In most cases,

all three mechanisms occur simultaneously. Their effects

may balance each other for a while, but eventually one

of the reactions prevails, leading to embrittlement of

the polymer (4).

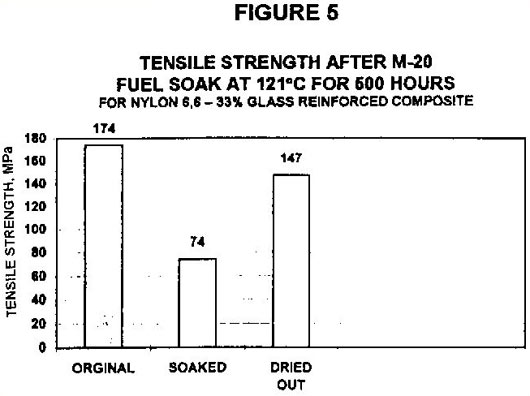

Figure 5 shows

the effects of M-20 fuel soak at 121ºC for 500 hours on

tensile strength for Nylon 6,6 – 33% Glass reinforced

composite. The tensile strength dropped significantly

after 500 hours at 121ºC when soaked in M-20 fuel. Nylon

6,6 is known to be adversely affected by exposure to

methanol. Methanol is absorbed by nylon and thus causes

reversible mechanical property changes due to

plasticization. Methanol will also hydrolyze nylon at

higher temperatures. Dried out samples after exposure to

M-20 fuel regained most of the original tensile strength

due to evaporation of absorbed fuel.

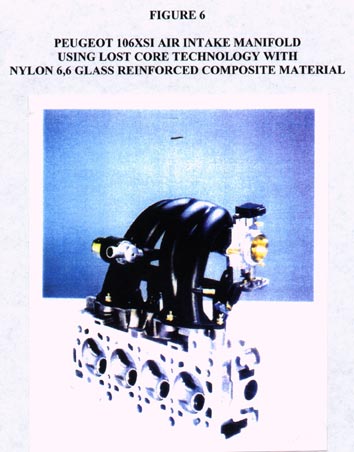

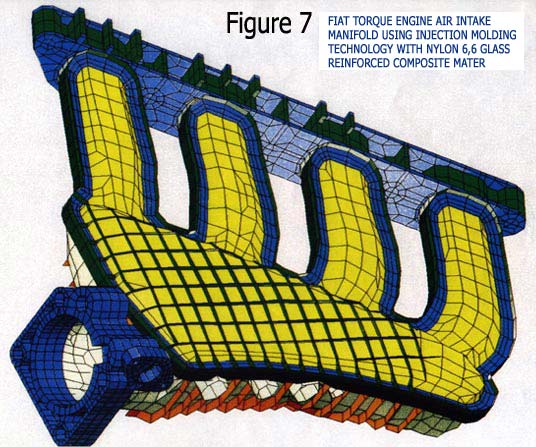

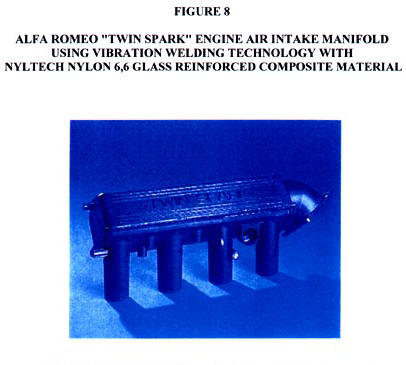

Figure 6, 7 and

8 shows Peugeot, Fiat and Alfa Romeo air intake

manifolds using Nylon 6,6 Glass reinforced composite

material.

CONCLUSIONS

Within the limit

of this study, it is shown that Nylon 6,6 – 33% Glass

reinforced composite material is suitable for intake

manifold applications. This material has high strength

and toughness, and excellent retention of properties

after heat aging.

REFERENCE

(1) Kohen

M.I., Nylon Plastics, John Wiley & Sons Inc., N.Y. 1973,

P. 313

(2)

Deanin R.D., Polymer Structure, Properties and

Applications, Cahner Publishing Co.,

N.Y., 1972, P. 88

(3) Murty

E.M., The Effect of the Automotive Fuel System

Environment on the Long

Term Durability of Reinforced Nylon, Thesis to GMI

Engineering and Management

Institute, April 15, 1989, P. 28

(4) Ibid,

P. 29

AUTHOR'S

BIOGRAPHY

Mr. Boney

Mathew, President & CEO, Mathson Industries, Inc., Troy,

Michigan USA.

Mr. Mathew's

background includes 16 years in the automotive and

plastics industry.

Prior to

starting Mathson Industries, Inc., he was a Marketing

and Technical Executive for Nyltech North America –

Joint Venture of Rhone-Poulenc – France and Fiat –

Italy.

He also served

as Plastics Manager for Teleflex, Inc.'s Automotive,

Aerospace and Medical Company. Mr. Mathew is the

inventor and co-inventor of several patents including

"Method of Making Fluorocarbon Coated Composite Braided

Hose Assemblies", "Hose End Fitting Assembly" and

"Expanded Fluoropolymer Tubular Structure, Hose Assembly

and Method for Making Same".

He is a member

of Society of Plastics Engineers, Society of Automotive

Engineers and ASEI. He has published and presented six

technical publications on various plastics and

composites at various international technical

conferences and is the co-author of "Passage to India, A

Comprehensive Study on the Indian Automotive Industry."

Mr. Mathew

earned a M.S. degree in Plastics Engineering from the

University of Massachusetts, Lowell, USA.

The appearance of

the ISSN code at the bottom of this page indicates SAE’s

consent that copies of the paper may be made for

personal or internal use of specific clients. This

consent is given on the condition however, that the

copier pay a $7.00 per article copy fee through the

Copyright Clearance Center, Inc. Operations Center, 222

Rosewood Drive, Danvers, MA 019223 for copying beyond

that permitted by Sections 107 or 108 of U.S. Copyright

Law. This consent does not extend to other kinds of

copying such as copying for general distribution, for

advertising or promotional purposes, for creating new

collective works, or for resale.

SAE routinely

stocks printed papers for a period of three years

following date of publication. Direct your orders to SAE

Customer Sales and Satisfaction Department.

Quantity reprint

rates can be obtained from the Customer Sales and

Satisfaction Department.

To request

permission to reprint a technical paper or permission to

use copyrighted SAE publications in other works, contact

the SAE Publications Group.

No part of this

publication may be reproduced in any form, in an

electronic retrieval system or otherwise, without the

prior written permission of the publisher.

ISSN 0148-7191

© Copyright 1999 Society of Automotive Engineers, Inc.

Positions and

opinions advanced in this paper are those of the

author(s) and not necessarily those of SAE. The author

is solely responsible for the content of the paper. A

process is available by which discussions will be

printed with the paper if it is published in SAE

Transactions. For permission to publish this paper in

full or in part, contact the SAE Publications Group.

|